|

|

|

|

|

|

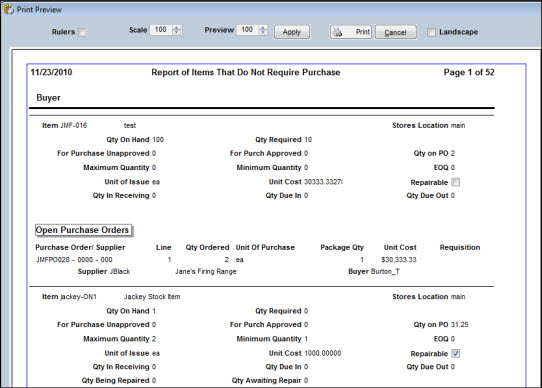

The information in this report gives buyers a list of items, covered by an approved requisition or purchase order, that are no longer needed. The buyer can then take action to have the requisition or purchase order canceled, thereby avoiding an investment in surplus inventory.

The program analyzes the order position of all items subject to the Reorder process. If pending order quantities plus current quantity on-hand less current requirements forecast an over-max condition, the program flags the item as unneeded. Site management has the choice of adjusting the over-max calculation by using the Tolerance tab of the Purchasing Setup Options window. Your system administrator can enter a money amount to the field labeled On Report of Unneeded Purchases, show items which, if purchased, will exceed Maximum Inventory Value by this amount.

Here is an example of how an item can become unneeded: A maintenance planner creates a work order that requires a quantity of five for a specific stock item. Subsequent processing of the work order triggers the reorder process to automatically generate a requisition to replenish inventory. During execution of the work, it is determined that all or part of the planned quantity will not be needed to complete the job. Processing of the work order into completed status cancels the requirements for unused material, thereby changing the item’s order position. If not canceled, pending orders for replenishment could potentially put the item in an over-max condition.

To Print the Unneeded Purchases Report:

|

1. |

From the Purchase Order Search window, click Go To and select Unneeded Purchases from the dropdown list. |

|

2. |

The report displays in the print preview window. |

|

3. |

Click Print to send the report to a printer. |

Note: The report can be scheduled to print from JobCop as a standard job if desired.