|

|

|

|

|

|

If your plant has multiple stores locations, TabWare's Multiple Warehousing feature provides a mechanism to manage inventory at the individual location level. At each location, you can assign an item to multiple bins. TabWare tracks the quantities at the bin level, generates reorders when minimum levels defined for that stores location are reached, and updates quantities when the reorder is received. You can transfer material among stores locations as needed and view item availability both for an individual location and in summary form across all stores locations for the entire plant. These multiple warehousing capabilities are only available only if the Multiple Warehousing module has been turned on through the Module Availability window of TabWare Setup.

Information on inventory items is kept at three levels:

General information applicable to all items regardless of storage location. Such information includes description, specifications, class code, hazard code, and other information about the item itself.

Stores location-specific information, including maximum, minimum, quantity required, quantity on purchase order, last date issued, and other information for each stores location.

Bin level information, such as bin number and quantity on hand.

To use the multiple warehousing feature, Multiple Warehousing must be selected from the Module Availability window in TabWare Setup. If this is not done, none of the other setup steps will have an impact. Once Multiple Warehousing has been turned on for a plant, the following setup parameters must be defined:

Select a default stores location in User Setup for users.

Define Stores Locations and default printer for each location in Validation Codes Valid Values. Optionally, in this window you can also enter custom descriptions for bin types.

Specify Transfer Request Numbering Methods and (optionally) define Transfer Request Rules in TabWare Setup-Customizing TabWare-Module Setup.

Those who have responsibilities that impact quantities in a stores location must be granted access to that location in TabWare Security.

If your plant is using the Multiple Warehousing feature, the following TabWare functions differ from a plant that manages a single stores location:

On the Equipment Tab you can indicate a stores location when planning a work order for an equipment location.

TabWare displays replenishment information for each stores location.

Displays transaction activity for individual stores locations and also for all stores locations in summary form.

Item Notebook Cross Reference Tab

Provides cross reference information on a per store basis as well as for all stores locations in summary.

This tab is only available if Multiple Warehousing is being used and provides inventory information for the entire plant, over all stores locations.

You are required to identify a stores location where the item will initially be stocked.

Issues are created for specific stores locations.

Items are received into specific stores locations.

Inventory-Restocking Repaired Items

Restocked items are returned to specific stores locations.

TabWare provides additional options accessed via the Go To button that enhance and facilitate your ability to fill replenishment requirements from other stores locations rather than through outside purchase if preferred.

Requisition Notebook - Item Information Tab

You must provide a stores location for each line if the requisition is for anything other than PM Master Plans, Standard Requests, services or for an item that is not in the item notebook.

Purchase Order Notebook - Line Item - Detail Tab

You must indicate the stores location for which the item is being purchased.

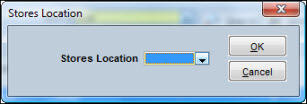

If your location has enabled Multiple Warehousing, you will need to identify the particular stores location in which an inventory transaction is taking place. The Stores Location popup precedes windows that specify general actions to be undertaken.

Click the dropdown arrow and select the appropriate stores location from the list. Click OK to move on to the next window.

As you use the TabWare documentation, be sure to keep in mind that there are differences in these operations between plants using Multiple Warehousing and plants that do not. Throughout the documentation, information that applies only to plants using Multiple Warehousing will be clearly identified.